Wholesale High Quality Wire Harness Manufacturers – Automotive wiring harness introduction 2 – Xuyao

Wholesale High Quality Wire Harness Manufacturers – Automotive wiring harness introduction 2 – Xuyao Detail:

Product Description

The development of China’s car industry is basically based on introduction. The introduction of models determines that the production of wiring harnesses can only be imitation or equivalent development. Therefore, the technological development of automotive wiring harnesses always lags behind the development of complete vehicles. At present, the popularity, safety and applicability of Chinese cars are the main models, so the technology of automotive wiring harnesses will still remain at the current level. Non-standardization, the situation of wire harness factories producing tens of thousands, or even hundreds of thousands of identical wire harnesses will be broken by the use of non-metallic conductive materials, and the production of integrated modules will be the first subject to be studied by wire harness factories in recent years.

Due to the advent of the fully automatic high-performance crimping machine with inspection, the new technology of piercing and joining, and the improvement of new equipment, as well as frequent changes in vehicle engineering and shortened supply cycles, the traditional, workshop-style, and manual wire harness production methods will gradually be produced. Therefore, improving independent development capabilities, carrying out parameter design, system design, and maintaining synchronization with vehicle design are the main development directions of China’s automotive wiring harness industry. With the diversification of wiring harness functions, OEMs will require parts factories to provide suitable spare parts immediately, which will also completely break the traditional production and supply methods.

At present, the more powerful wiring harness factories have assembled to the location of the OEM to meet the requirements of rapid response. In the United States and Europe, the supply time limit of the wiring harness factory has been shortened to 90 minutes, which requires the wiring harness factory not only to have rapid response The technical management system and reliable quality assurance system must also have a smooth material system, as well as a staff training system. The format of China’s car production base has basically been formed. Driven by the OEM, it has become a base for large-scale production of wire harnesses. The production of wire harnesses in Northeast and East China accounts for more than 63% of the national market, and its sustainable development capability is also better than other regions.

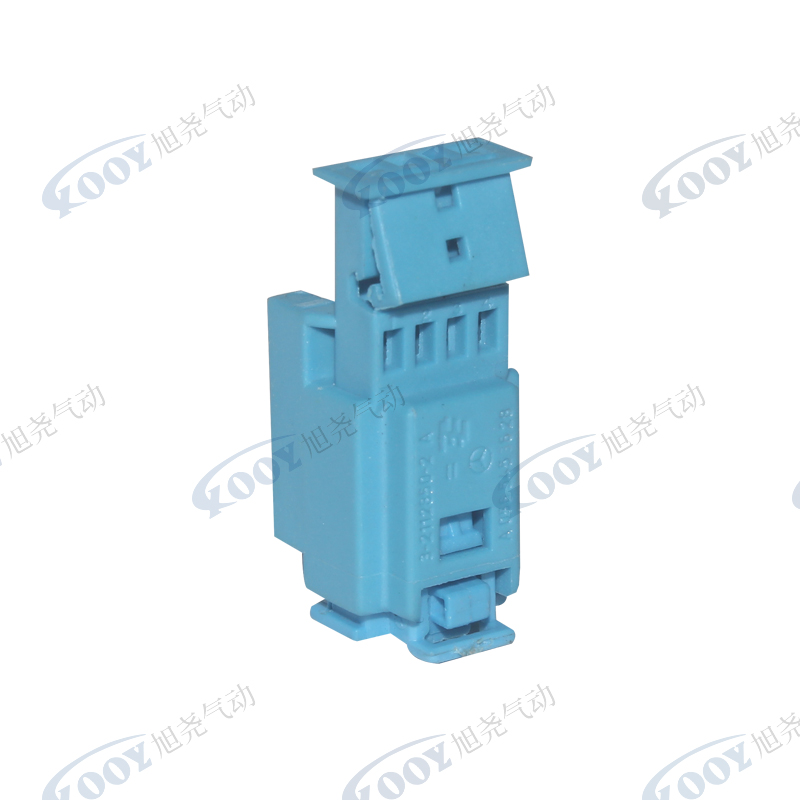

details picture

Product detail pictures:

Related Product Guide:

While using the "Client-Oriented" company philosophy, a demanding high-quality management method, innovative producing products and also a sturdy R&D workforce, we always deliver premium quality merchandise, superb solutions and aggressive selling prices for Wholesale High Quality Wire Harness Manufacturers – Automotive wiring harness introduction 2 – Xuyao , The product will supply to all over the world, such as: Denver, Sierra Leone, Colombia, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!